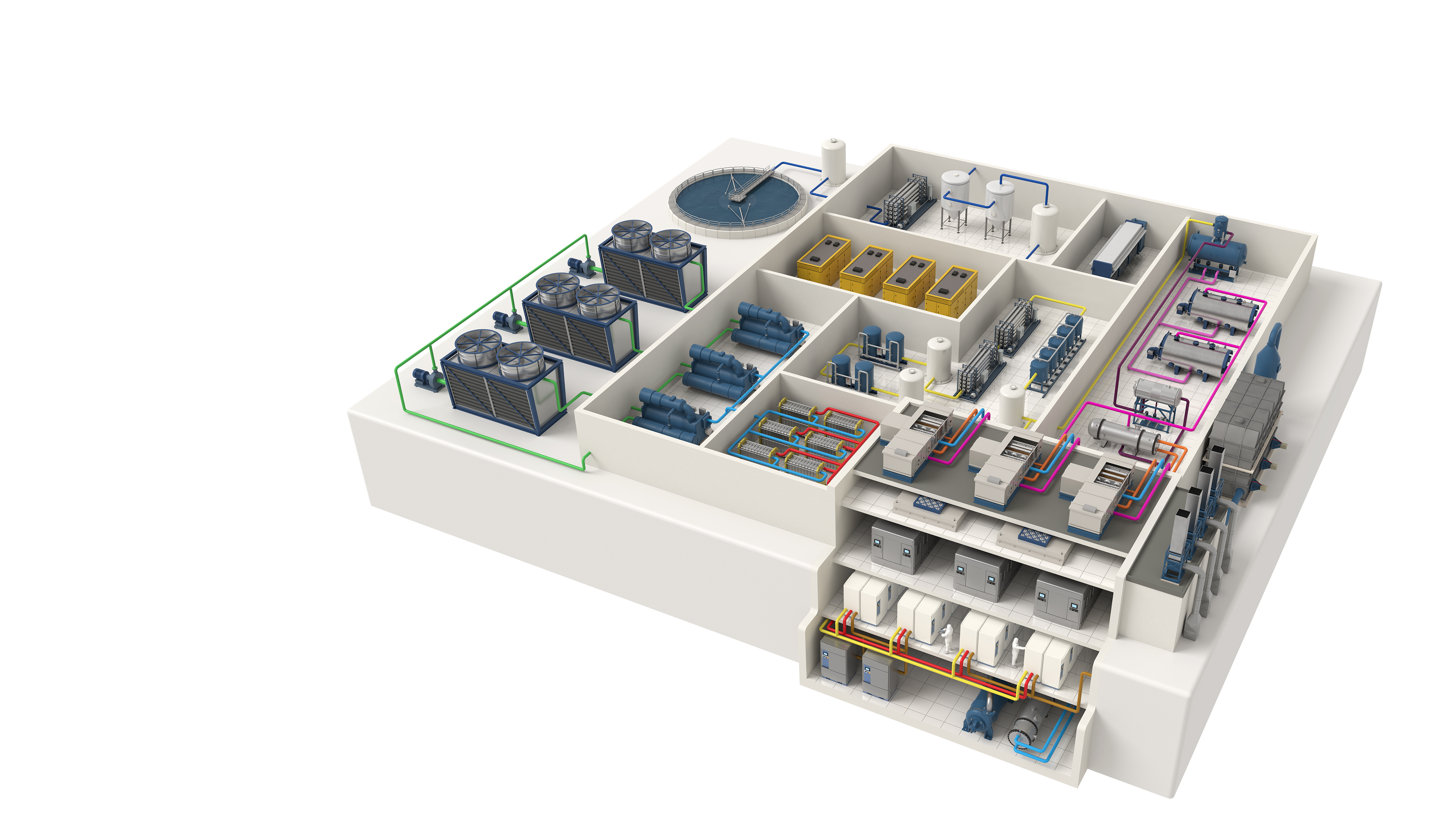

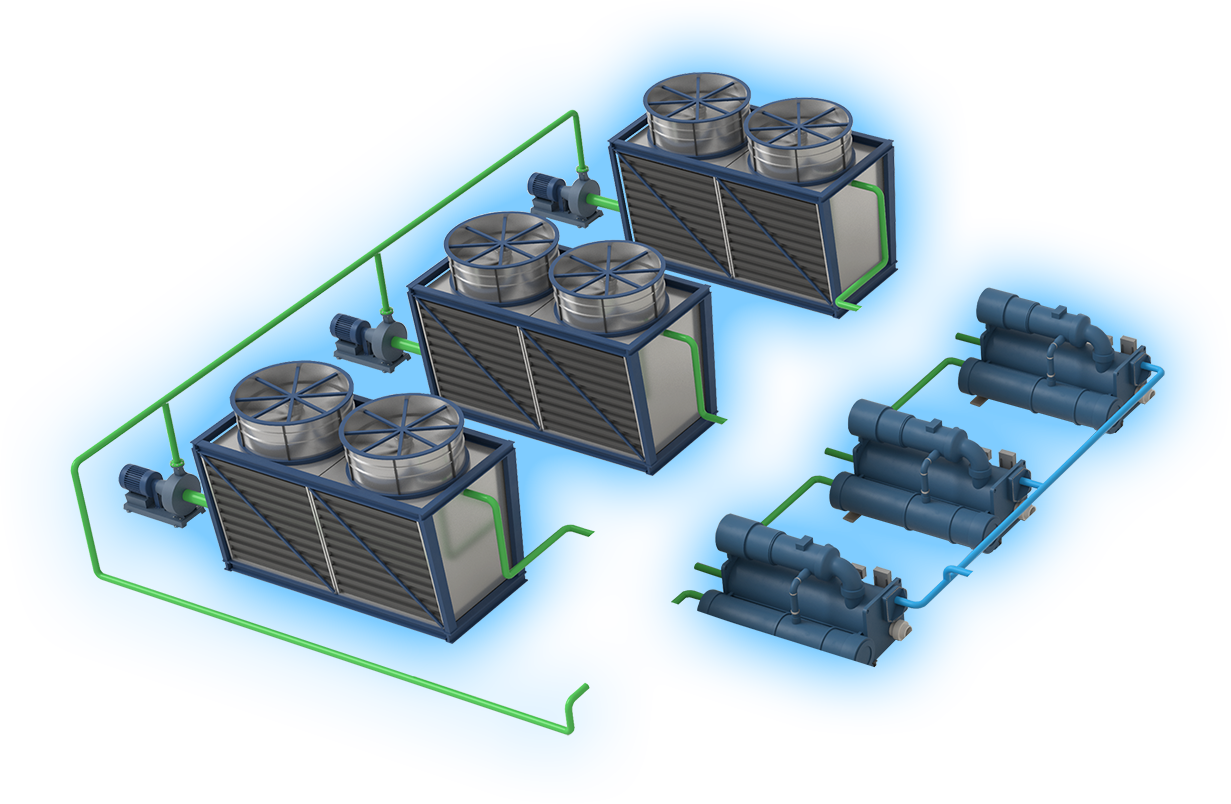

Cooling towers are a fab's main source of heat rejection, with chilled water systems being the primary source of heat load. This connection impacts other critical supporting assets, too (e.g., air handlers and compressors, process vacuum and process cooling water). As open systems, cooling towers are prone to airborne contaminants that can compromise chiller efficiency. Proper system management is critical to fab efficiency and uptime.

Driving Reliability and Productivity In Microelectronics Production

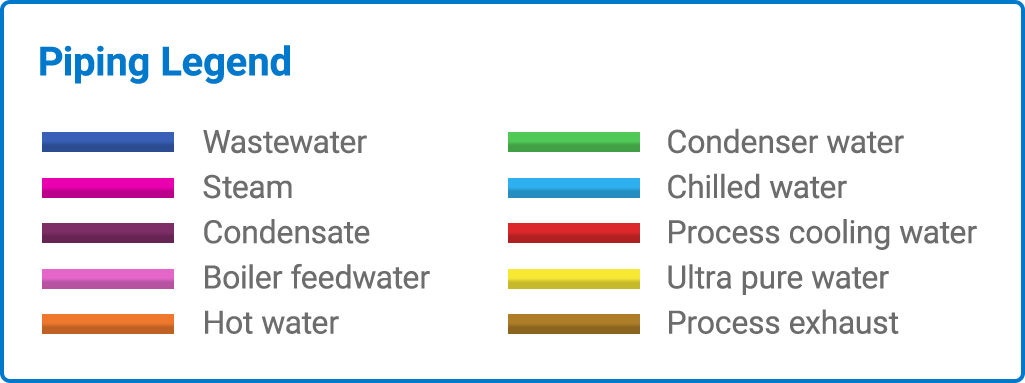

Click on a solution for details

Sistemas de enfriamiento de agua

- Are you challenged to maintain approach temperatures at or below design manufacturer specifications?

- Are you dissatisfied with the tools available to quantify water, energy, waste, cost and/or risk reduction?

- Are you challenged on how to best use available reclaimed water sources while accounting for variable water quality?

Our 3D TRASARTM Technology for Cooling Water detects out‑of‑spec conditions, determines the correct response and helps deliver operational and cost efficiencies. 3D TRASAR programs help fabs use reclaimed process rinse waters as cooling tower make-up and, in some cases, eliminate the use of fresh water for cooling towers – all while supporting asset preservation.

More reasons to consider a 3D TRASARTM for Cooling Water program:

- Scale and fouling control helps minimize energy consumption

- Optimized cycles of concentration help minimize water use

- Real-time system data via performance dashboards

- 24/7/365 monitoring supports peace of mind

- In one example, 7.2 million gallons of water were saved in the first year, with nearly $115,000 in total cost of operation (TCO) savings

Nalco Water filtration systems help minimize system deposits in small-tolerance cooling water systems to help ensure cooling water supply

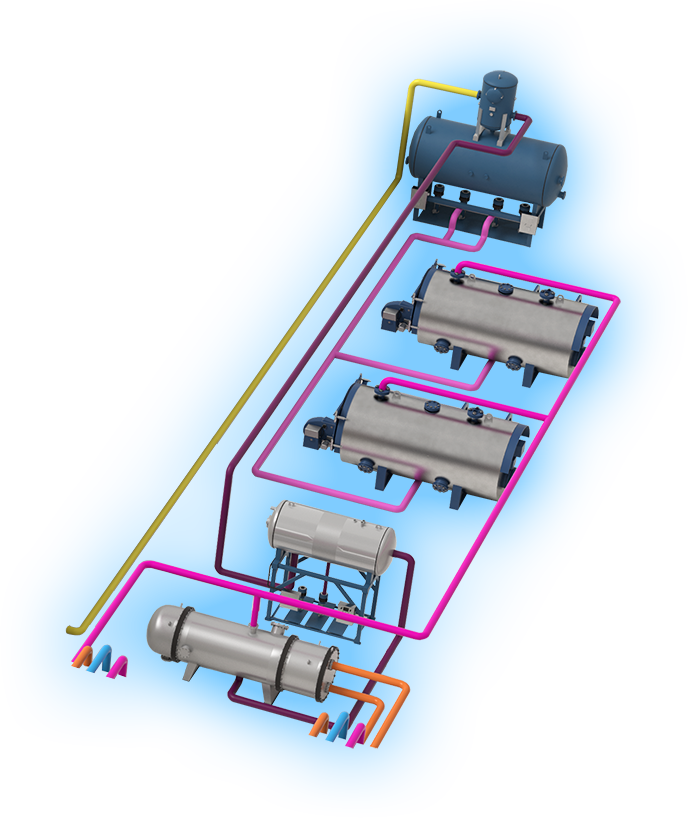

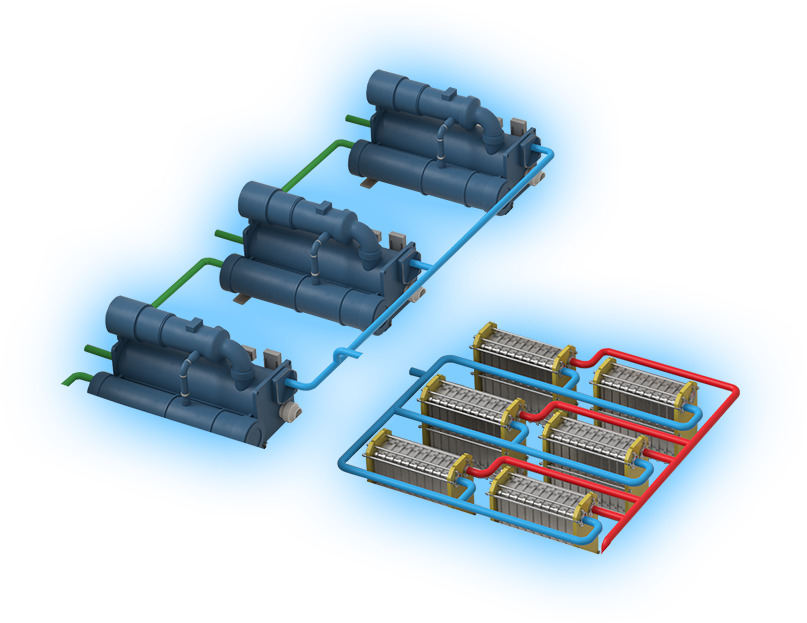

Sistemas de calderas

For some fabs, steam-generating equipment provides thermal energy necessary for process. These systems impact a range of assets including air handlers and heat exchangers for hot UPW and secondary hot water processes.

- Have you considered these systems as a potential opportunity for water and energy savings?

- Have you experienced premature failures requiring boiler retubing?

- Would you benefit from new water treatment monitoring tools to help ensure your boilers are operating at the lowest total cost?

Our 3D TRASARTM Technology for Boilers programs are designed to improve competitive advantage and optimize total operating costs. We help you produce reliable, safe and cost‑effective steam using a total-system approach.

Más razones para trabajar con Nalco Water:

- For steam boilers, oxygen scavengers, internal treatment and condensate corrosion inhibitors

- Tecnología que monitorea y controla el tratamiento interno en tiempo real y la corrosión del sistema previo a la caldera

- Steam system protection with programs tailored for your operational and environmental needs

- The potential for significant return on investment via savings in fuel, water and extended asset life

Hot Water Systems

For some fabs, hot water systems provide thermal energy necessary for process. These systems impact a range of assets including air handlers and heat exchangers for hot UPW and secondary hot water processes.

- Have you considered these systems as a potential opportunity for water and energy savings?

- Have you experienced premature failures requiring heat exchanger cleaning or replacement?

- Would you benefit from new water treatment monitoring tools to help ensure your hot water systems are operating at the lowest total cost?

Our emphasis on controlling scale and corrosion in a fab's hot water system helps ensure a reliable manufacturing environment.

Más razones para trabajar con Nalco Water:

- 3D TRASARTM Technology may be used in some cases to provide real-time process visibility to critical water parameters including conductivity, corrosion rates, hydraulic losses and pH

- TRAC hot water programs help ensure excellent corrosion control for a wide range of metallurgies

- The potential for significant return on investment via savings in fuel, water and extended asset life

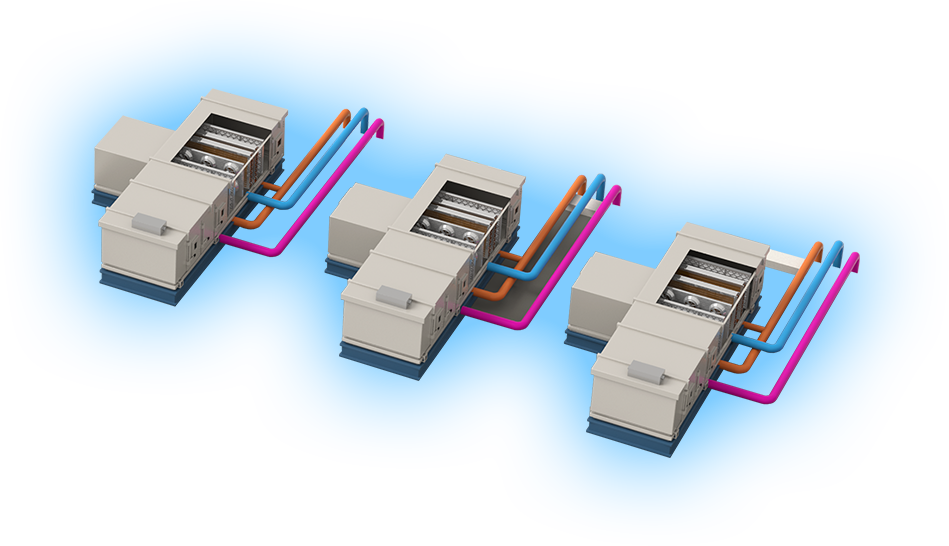

Climatizadores

Air-handling systems deliver fresh air make-up at a specific temperature and relative humidity. Even slight deviation from setpoints can profoundly affect product quality. Without reliable and efficient air-handling systems, uptime may be at risk -- and the cost of downtime is high.

- Are you able to reliably maintain your target temperature and relative humidity setpoints?

- Are you challenged to maintain adequate chilled water capacity to meet sitewide demands in warmer months?

- Are you able to accurately measure and document energy savings from your coil cleaning program?

Our COIL-FLO coil cleaning program helps improve coil efficiency and air quality, resulting in more airflow and cooler air.

More reasons to consider COIL-FLO for your air handlers:

- Helps minimize air handler energy costs

- Helps optimize filter life to reduce filter replacement costs

- Data-based documentation of energy savings

- Cleanings performed by dedicated, trained technicians

- COIL-FLO helped one semiconductor fab save 1.22 million kWh, valued at $117,900 USD, per year

Scrubbers

Scrubbers support environmental compliance and protection by removing contaminants from process exhaust air streams. Highly concentrated gas streams may also have dedicated point-of-use (POU) scrubbers. Minimizing biofilm and scale on packing material is critical to scrubber performance.

- Does unplanned maintenance on your scrubbers impact capacity?

- Are you challenged to accurately trend and monitor scrubber performance?

- Do you feel uncertainty over whether your scrubbers are accounted for in your site's water management plans?

Our water treatment programs help ensure efficient scrubber performance and environmental compliance for fabs by controlling scale and microbial deposits.

More reasons to partner with Nalco Water for scrubber water treatment:

- Our programs support efficient air scrubber operations

- Help prevent unplanned maintenance

- Help minimize risk of scale and microbial deposits

- Hands-off chemical treatment programs support human health & safety

Fab and Sub-Fab

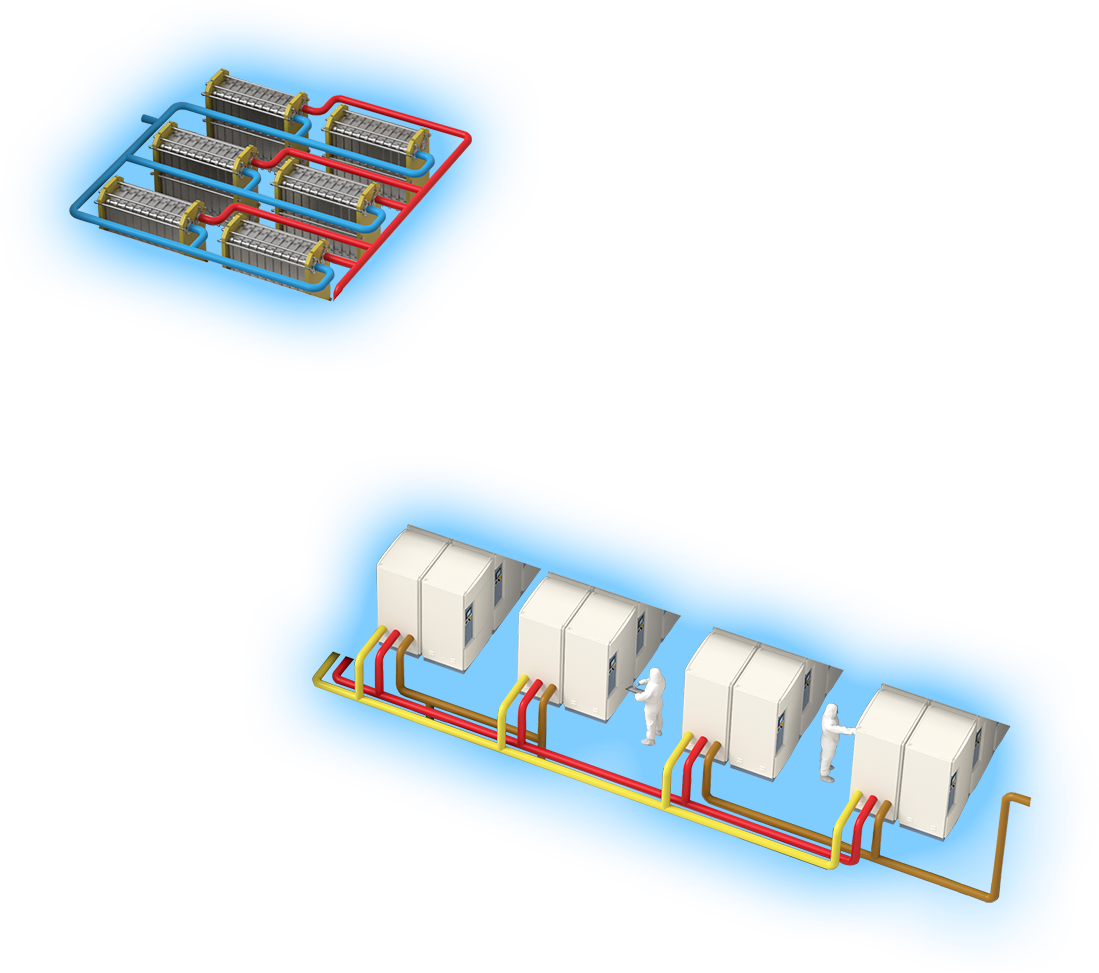

Self-contained OEM cooling circuits remove heat from various manufacturing processes across a fab. These closed-loop systems often have stringent water quality specifications; improper water management can lead to unplanned downtime and expensive asset damage.

- Have fab engineers or tool owners reported process-related issues that affect tool performance?

- Are there specific tool-cooling requirements that are outside typical fab operating conditions?

- If you experience tool failures, do you have the analytical capabilities to properly identify root cause?

Our programs for PCCL (process-critical closed loops) help semiconductor tool manufacturers ensure high uptime levels and avoid problems within the cooling water circuits of tools.

More reasons to partner with Nalco Water to protect your self‑contained cooling circuits:

- Consistent analytical support across your enterprise

- Global, enterprise-wide deployment capabilities

- Tool-specific water treatment solutions

- Hands-off chemical treatment programs support human health & safety

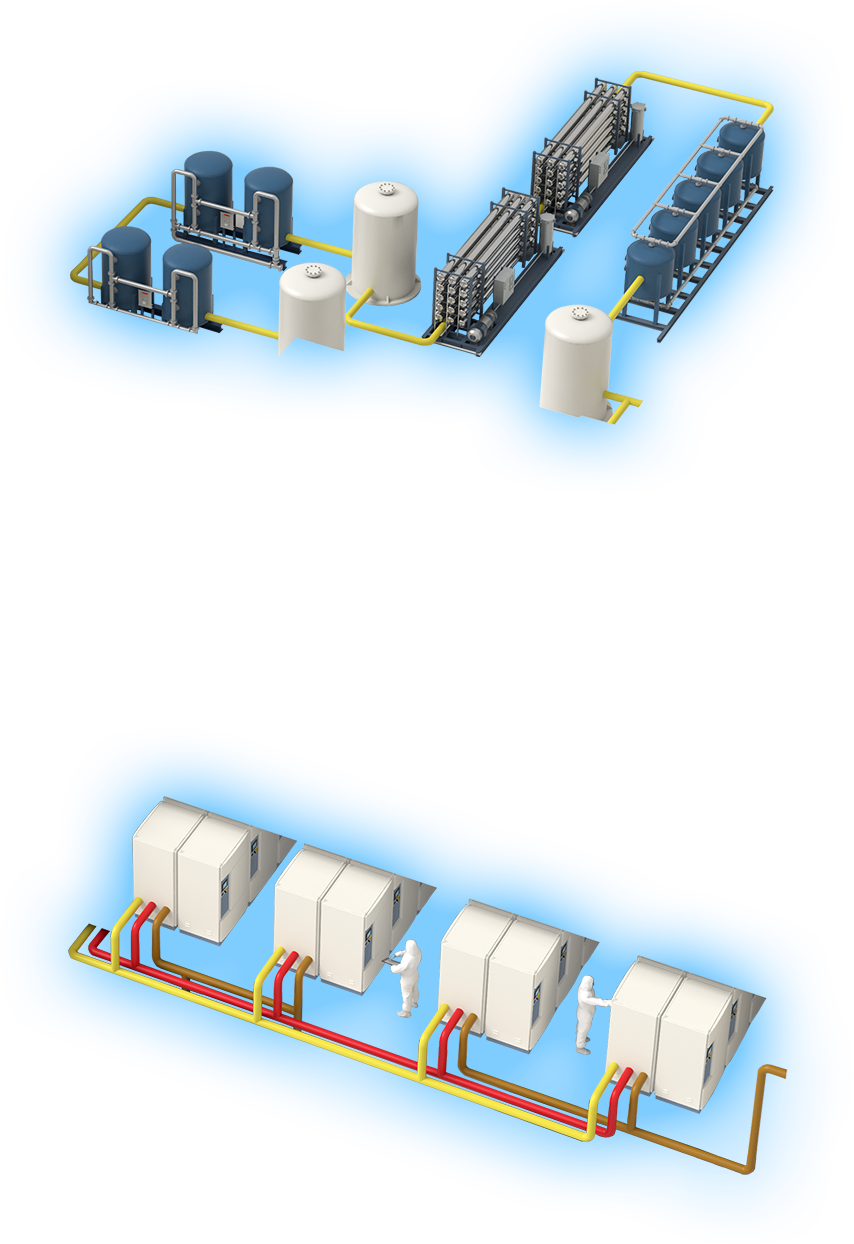

Process Cooling Water

Process cooling water (PCW) systems are essential to production, providing reliable heat removal from the manufacturing processes. Efficiently operating PCW systems protect expensive production assets and help ensure uptime.

- Do fab engineers report concerns with flow challenges, tool failures, or fouled flow gauges?

- Do your engineers lack sufficient tools to manage and validate that PCW loops are performing to the fab's expectations?

- Are you challenged to detect PCW system disruptions that occur when fab tools are added or reconfigured?

Our expertise in controlling scale, corrosion and microbio in cooling water systems helps protect the water that ensures a reliable manufacturing environment.

More reasons to partner with Nalco Water for PCW treatment:

- 3D TRASARTM Technology for Cooling Water gives real-time visibility to critical process water parameters including conductivity, corrosion risk, hydraulic losses & pH

- TRAC cooling water programs ensure excellent corrosion control for a wide range of metallurgies across a broad range of conductivity requirements

- Nalco Water filtration systems help minimize system deposits in small-tolerance cooling water systems to help ensure cooling water supply

- With 3D TRASARTM Technology for Cooling Water, we helped one fab save 10.9 million gallons (41.3 million liters) of water per year and reduce azole discharge by 64% in their PCW system

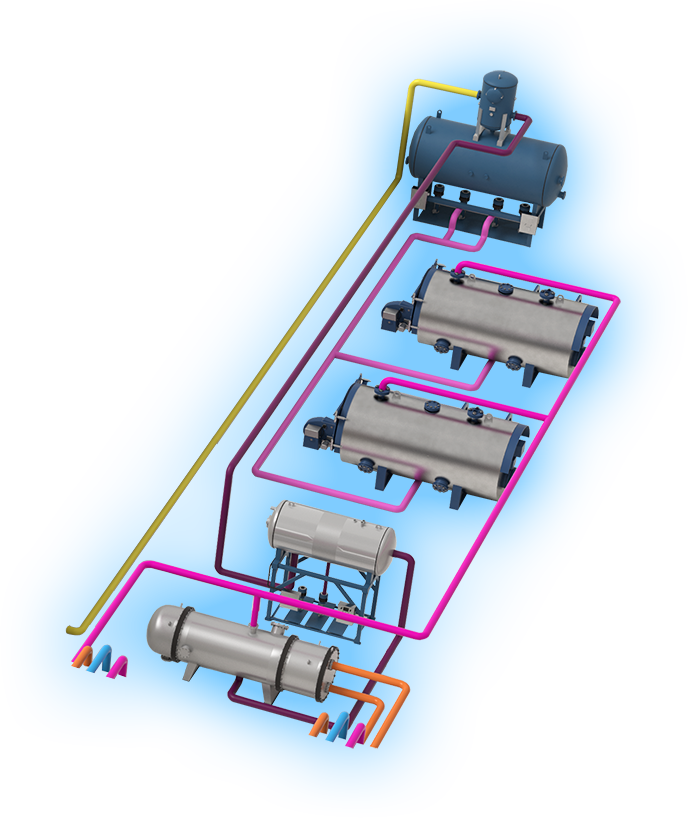

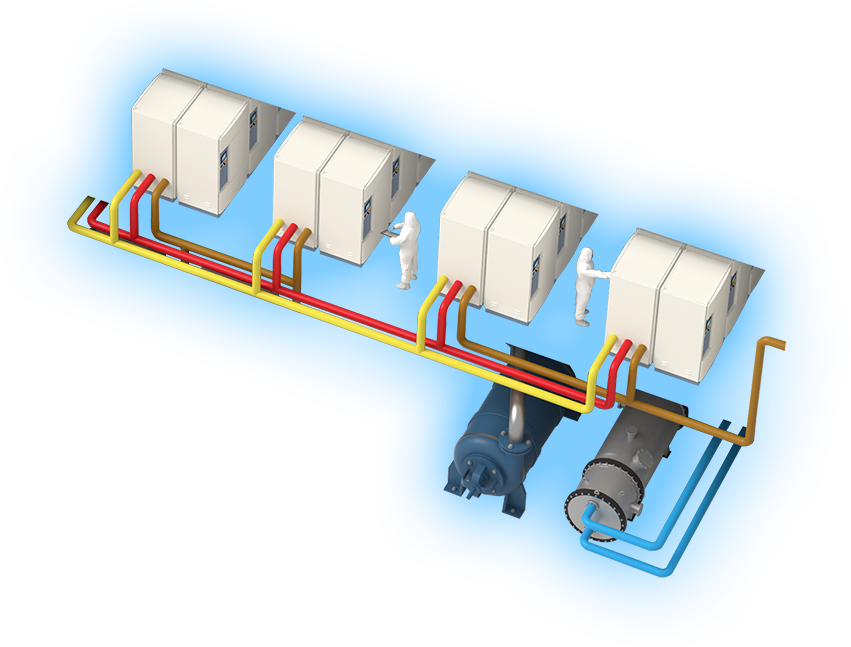

Process Vacuum

Process vacuum (PVAC) systems ensure specific tool conditions to enable reliable wafer processing. Heat rejection from PVAC systems requires efficient heat transfer. Improper water management in this area has the potential to compromise operational performance and long-term asset life. In severe cases, costly unplanned downtime can result.

- Do you monitor your seal water temperatures and, if so, have you experienced high temperature alarms?

- Do your PVAC heat exchangers require maintenance cleaning to restore design performance?

- Are you concerned that your program approach and monitoring tools are inadequate to maximize performance of your PVAC systems?

We solve PVAC problems on-site using a mechanical, operational, and chemical approach. Our experienced staff is supported by extensive lab and local analytical resources, including root-cause microbial and corrosion analyses.

More reasons to partner with Nalco Water for PVAC water management:

- We helped one fab reduce unplanned maintenance by 95%+ and reduce iron levels in system water by 97%, saving $85,700 per year with a tailored PVAC treatment program

- The programs we develop together include training of fab personnel to implement and track execution to help ensure the desired results are achieved and documented

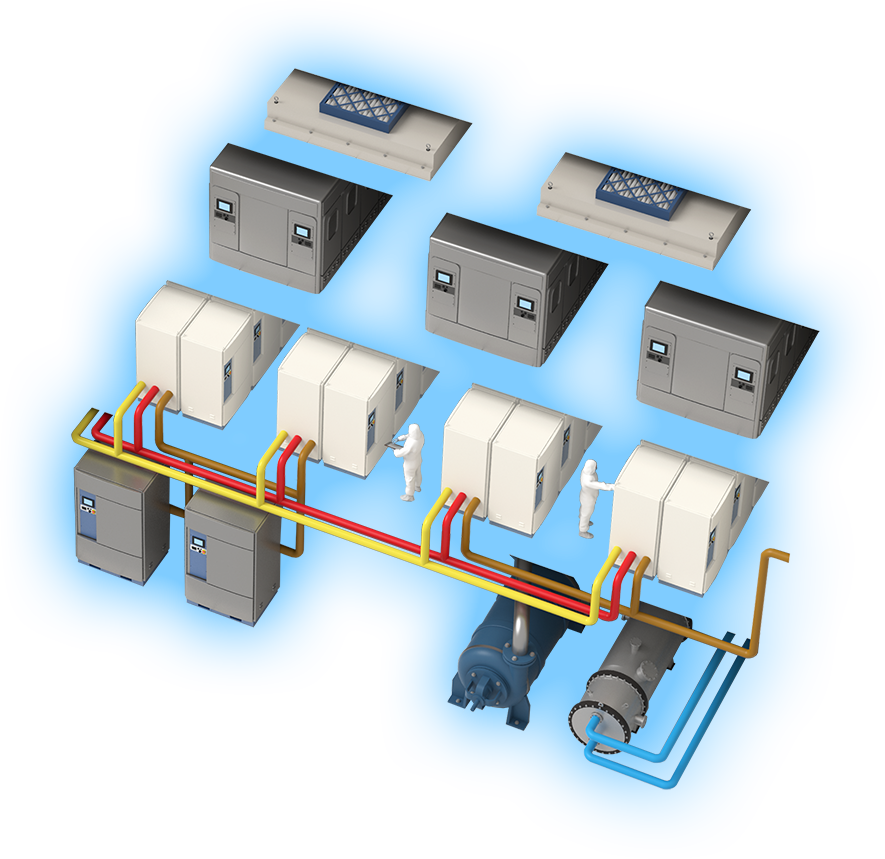

Chilled Water Systems

Chilled water is a key link between the central utility building and the rest of the fab. Chillers are often the second largest energy consumer in the fab. These systems impact a range of assets including air handlers, PCW, air compressors, process vacuum systems and more.

- Are you concerned about your ability to properly manage dead legs and low-flow zones in your chilled water systems using your current plan and monitoring tools?

- Are you struggling to maintain redundancy due to derated chiller performance caused by fouling or plugged tubes?

- Have you completed a chiller efficiency study to verify your equipment is operating at the rated capacity for the specified loading conditions?

Our emphasis on controlling scale, corrosion and microbio in a fab's cooling water helps ensure a reliable manufacturing environment.

Más razones para trabajar con Nalco Water:

- 3D TRASARTM Technology for Cooling Water gives real-time process visibility to critical water parameters including conductivity, corrosion rates, hydraulic losses and pH

- TRAC cooling water programs ensure excellent corrosion control for a wide range of metallurgies across a broad range of conductivity requirements

- Nalco Water filtration systems help minimize system deposits in chilled cooling water systems to support consistent, reliable cooling water supply

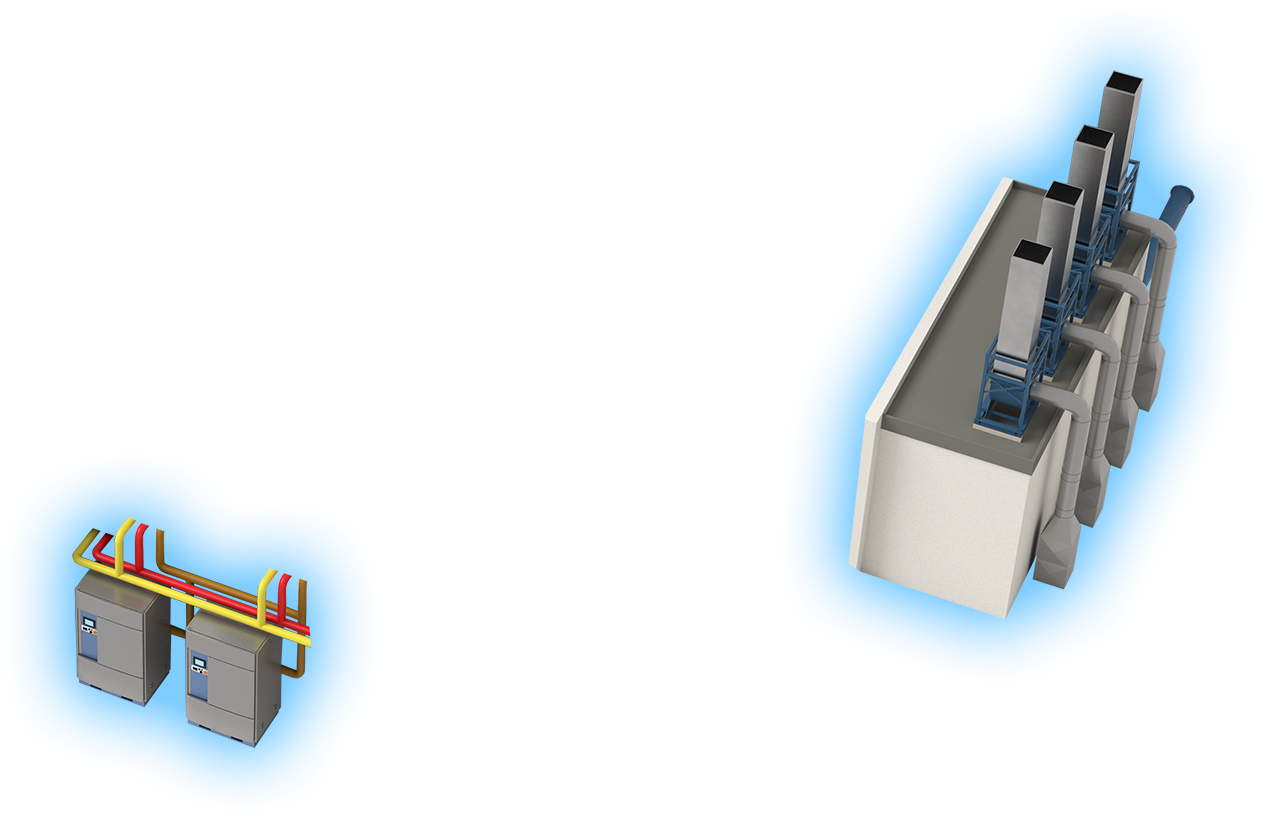

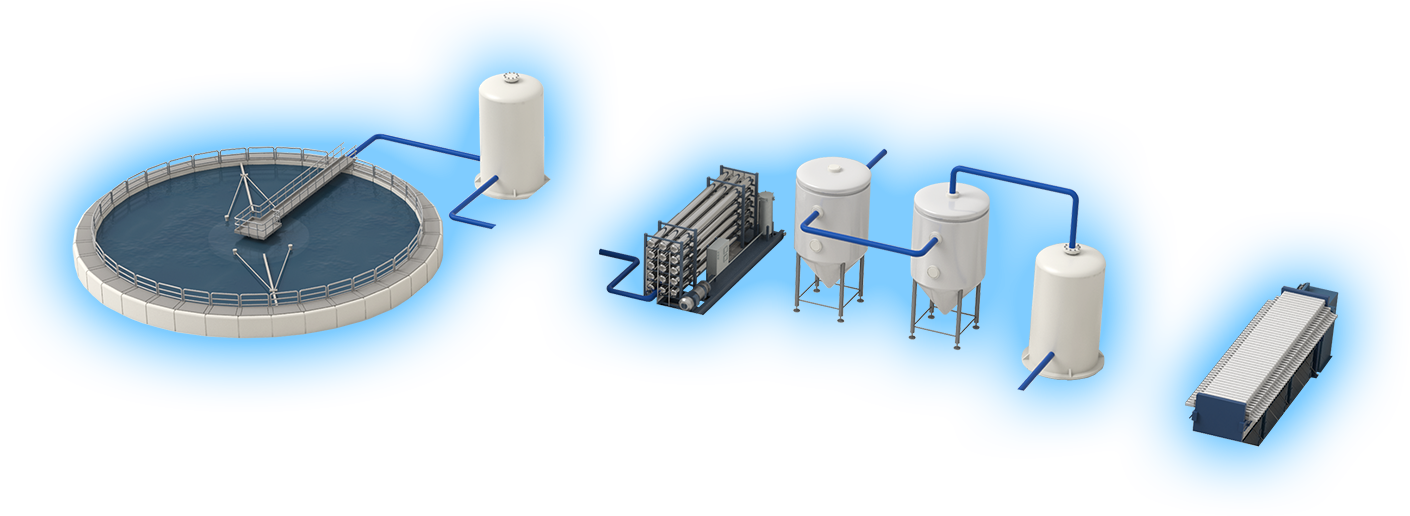

Wastewater

Microelectronics fabs generate significant volumes of wastewater. Selection of the proper treatment strategies should balance considerations such as safety, compliance, reliability and cost, all factored into the fab's total water footprint. With proper treatment, much of this water can be reused in other applications.

- Is your wastewater treatment process a bottleneck to maximizing plant production capacity?

- Can your current wastewater treatment program accommodate fluctuations caused by advanced manufacturing processes and/or evolving discharge constraints?

- Do you feel your wastewater treatment approach has kept up with changes in your fab's water-related sustainability goals?

Our post-treatment expertise helps control heavy metals and fluoride in fab wastewater to support regulatory compliance and optimize operating costs.

Más razones para trabajar con Nalco Water:

- 3D TRASARTM Technology for Wastewater programs help deliver environmental compliance at the lowest total cost of operation

- DBOOM capabilities (Design, Build, Own, Operate and Maintain) for specific wastewater challenges

- NalmetTM heavy metal removal programs to treat chelated metal streams with improved aquatic toxicity levels

- Optimized sludge dewatering to help minimize disposal costs

Ultra-Pure Water

Ultra-pure water (UPW) is a fab's lifeblood utility, carrying process chemistry to the wafers and rinsing them throughout the chipmaking process. Advanced technology nodes require continuous improvement in operational efficiency and reliability of the UPW system. In this context, managing and controlling chemistries (e.g., antiscalants, cleaners and microbio programs) that support UPW reliability becomes even more critical. Balancing system reliability, water/energy efficiency, asset longevity, and total cost of operation are possible with a properly designed treatment chemistry program.

Our PermaCareTM product line and control technologies help prevent RO problems and ensure high quality permeate.

Más razones para trabajar con Nalco Water:

- Highly effective antiscalants help prevent mineral deposits from membrane build-up, causing fouling and downtime

-

3D TRASARTM Technology for Membranes offers:

- • Precise antiscalant dosing

- • Defense of membranes against oxidant spikes

- • Optimized recovery rates and cleaning schedules

- Cleaners and biocides specifically formulated to remove mineral scale, insoluble scale, organic fouling, or microbial residues

Waterborne Pathogen Risk Management

Many of the water-based utilities in a fab carry potential risk for waterborne pathogens, including Legionella. Maintaining a safe working environment for employees is a hallmark of the Microelectronics industry. Having a comprehensive management plan to monitor and mitigate waterborne pathogen risk supports employee and community safety.

- Have you developed and implemented a water risk management program that aligns with ASHRAE Standard 188 guidelines?

- Do you understand which systems in your facility pose waterborne pathogen risk and how to manage those risks?

- Does your water risk management plan provide visibility to help ensure worker protection along with clear protocols for preventive maintenance, monitoring and, if needed, remediation?

We offer a holistic approach to waterborne pathogen risk management, which can include analytical monitoring, long-term control strategies and/or short-term remediation and emergency services as needed.

Más razones para trabajar con Nalco Water:

- We conduct more Legionella analysis than any other organization in the world. We are global experts in water safety with 30+ years of experience

- Online cooling tower disinfection: Our highly trained and certified service engineers will disinfect the operating system over a six-hour period, then safely return the system to normal operating conditions

- Offline tower disinfection: Our certified service engineers complete a full physical cleaning of the tower decks, fan housing area, distribution nozzles, tower fill, and water sump

- Inspection and certification: Nalco Water certified according to guidelines published in the OSHA Technical Manual (Section III: Chapter 7, Legionnaires’ Disease)

- With 15,000+ cooling tower water management plans implemented globally, we can help you develop a plan tailored to your operation and compliant with ASHRAE Standard 188

Analytical Support

Your advanced manufacturing processes require a partner with deep analytical support capabilities. Comprehensive technical services support root-cause analysis and help determine the right solutions to support product quality, operating efficiency, and sustainability.

- Are you confident that your analytical data sets focus on the parameters critical to system health?

- Do you have access to technical resources needed to perform a conclusive root-cause analysis?

- When you have water-related problems, can you reliably, accurately, and repeatably turn analytical information into specific actions?

Our global analytical support enables fast, thorough troubleshooting and problem resolution. Lab services include:

- Water analysis (UPW, PCW, wastewater, cooling water, reclaimed water)

- Microbial analysis

- Deposit analysis

- Failure analysis (metallographic)

- Reverse osmosis (RO) membrane autopsies

- Corrosion coupon analysis

These types of analyses can help fabs make quick, smart decisions on topics including:

- Resolving PCW issues that impact production

- Reclaiming new water sources as cooling water make-up to reduce water consumption and water footprint

- Optimizing RO system performance